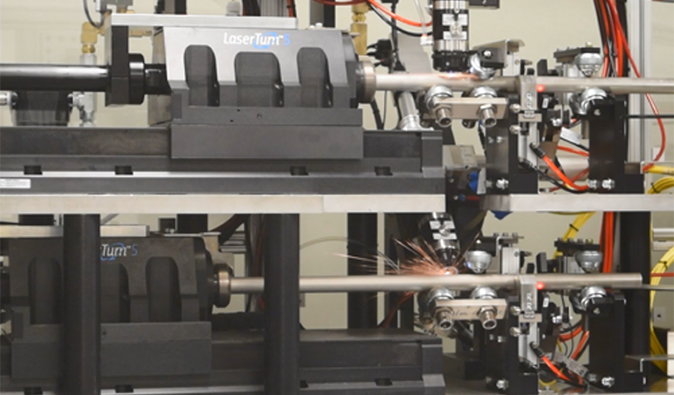

A fully automated production system that is used for high-volume tube orders and standalone laser cutting system is used for low-volume orders, short tubes, or prototyping. The full production system has inspection, laser cutting, and post-processing systems. The production machine is automated by a programmable logic controller and the tubes are conveyed from system to system by a robotic arm making it ideal for high-volume tube orders of a single filter type. The standalone laser cutting system is manually loaded and operated however has high flexibility of what can be produced.

Laser Cutting

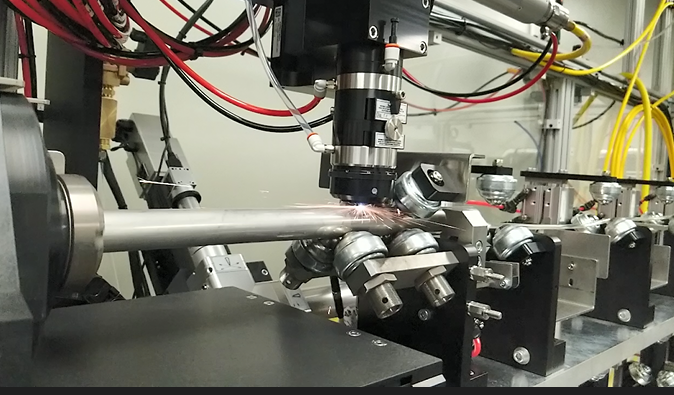

Our laser cutting process uses 1 kW, 1070 nm fiber lasers with excellent beam quality (M2 < 1.1) for precise and high-speed cutting. These lasers were chosen for their high throughput and fast cutting speeds, precise and repeatable high-quality cutting, finer machining capabilities, reduced downtime, and minimal maintenance. The cutting heads that are used allow for high-precision applications at laser power of up our maximum output of 1 kW.

As laser processing occurs, blowers pass air through the tube with a combination of air of water to carry molten metal away. Water is sprayed at the site where cutting occurs via a novel wet cutting apparatus. The wet cutting apparatus inserts vinyl tubing through the metal tube where water is pumped to reduce heat and the recast of material. The wet cutting process can reduce up to 99% of the slag and recast that typically would build up on the interior of the tube and potentially clog the slots. The molten metal, water, and air are all conveyed through a vacuum box and out of the system to produce a clean finished tube with minimal debris.

The motion control utilizes an integrated linear/rotary motion platform which can achieve up to 2 meters per second and 800 RPMs. The linear X-axis motion stage features 300 mm of travel. For tubes exceeding the linear travel length, the tube is cut in sections and the X-stage is reset after each section. Once the cutting process is complete, the tube is cut to the specified length. The combination of these integrated systems allows for high quality and high throughput production of laser cut perforated metals tubes.

Inspection and Quality Control

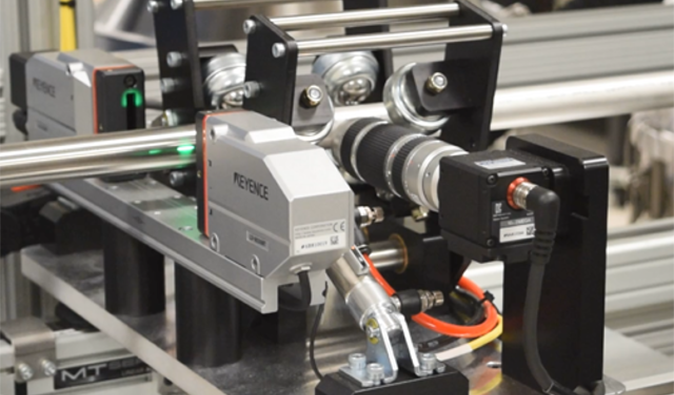

All tubes that are produced go through an inspection process to collect information and ensure the quality of all finished filter tubes. The inspection system consists of two separate operations, incoming inspection of blank tubes entering the system and outgoing inspection of finished tubes leaving the system. Incoming tubes must be within a specified roundness and straightness to ensure a successful cut. This is essential for the fully automated production system but not as critical when using the standalone cutting system. All finished tubes are inspected with the outgoing inspection system to ensure they are within the required cut specifications. The purpose of the inspection system is to guarantee the quality of the product and provide accurate results for each completed tube.

Incoming Inspection

The incoming inspection is used in the fully automated production system to reduce the chance of failure. The incoming inspection system features a high-speed, high-precision optical micrometer measuring instrument. The optical micrometer is accurate to ±2 μm and scans the surface of the tube to check for defects and ensure the roundness and straightness are within the required cut specifications. This is an important step in the process to ensure a successful cut.

Outgoing Inspection

The outgoing inspection is the final step of the production process. The outgoing inspection system utilizes an industrial quality control machine vision with a high-speed camera and a 200x microscopic zoom lens for final inspection of finished tubes. The camera collects data on the tube and can determine information such as the maximum, minimum of each slot length and width, as well as the average, and then calculate the open area of the tube. The machine vision processes multiple measurements and concludes with a pass or fail grade.

Post-Processing

A post-processing system is available for final cleaning of the tubes. This system cleans the tubes in three stages: an ultrasonic cleaning bath, a rinse tank, and a high output dryer that can reach a temperature of 1200° F. Depending on the application various levels of post-processing can be added if additional or more thorough cleaning is required such as electropolishing.